WELCOME TO

PJR ENGINEERING

Leading SA In Refurbishing Brick Making Machinery

” PJR Engineering blends expertise with precision to refurbish used brick making machinery, providing clients with top-tier equipment without the brand new price tag.”

PJR Engineering

Restoring Excellence

Unmatched Quality and Service in Brick Making Machinery Refurbishment

PJR Engineering is a leader in refurbishing high-end used brick making machinery, dedicated to delivering exceptional value to our clients.

Our commitment to professionalism and quality is reflected in every piece of brick making equipment we restore, ensuring that each machine meets the highest standards of performance and reliability.

With a focus on customer satisfaction, we provide not only efficient, high-quality repurposed brick making machinery, but also unparalleled customer support, guiding our clients through every step of the process.

At PJR Engineering, our high standard of workmanship guarantees that our refurbished brick manufacturing machinery performs like new, offering you a cost-effective solution without compromising on excellence.

” PJR Engineering blends expertise with precision to refurbish used brick making machinery, providing clients with top-tier equipment without the brand new price tag.”

OUR TECHNICAL SERVICES TO YOU

From expert machinery refurbishment and precision part manufacturing to on-site inspections and installation support, our skilled technicians are committed to ensuring that your equipment operates at peak performance.

REFURBISHMENTS

We expertly handle the entire process, from safely dismantling your machinery on-site to transporting it to our workshop in Eikenhof.

Our skilled team ensures that every step is managed with precision and care, preparing your equipment for a professional refurbishment that restores it to like-new condition.

AGGREGATE BATCHING

Our aggregate batching system is engineered for precision, ensuring that exactly measured quantities of raw materials are delivered to the mixer every time.

This system is designed to optimize the efficiency and consistency of your brick making process, contributing to high-quality end products.

INSTALLATIONS

Our team carefully assess your location to ensure that the space can accommodate the complete brick making machine, guaranteeing a smooth and efficient setup.

By addressing potential challenges upfront, we help you avoid costly delays and ensure that your equipment operates at peak performance from day one.

REPLACEMENT PARTS

Our team also specialises in manufacturing premium replacement parts for VB1, VB4, and VB4X brick making machines, ensuring that your equipment continues to perform at its best.

We produce parts for 1,000-litre and 1,500-litre counter-current pan mixers, maintaining the reliability and efficiency of your mixing processes.

LASER & PLASMA CUTTING

Our equipment ensures accurate and efficient cuts, allowing us to create high-quality components with exceptional detail.

Whether for custom parts or large-scale projects, our laser and plasma cutting services deliver the precision and reliability your business demands.

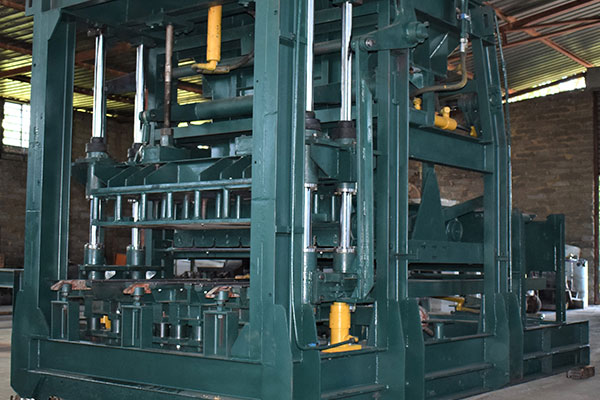

COMPLETE BRICK MACHINES

At PJR Engineering, we specialise in the refurbishment of high-end, used brick making machinery, offering a cost-effective alternative to new equipment without compromising on quality.

VB4 and VB4X brick machines

VB4 and VB4X brick machines are better suited for larger scale operations with production rates of 18 000 M140 hollow blocks, 90 000 stock bricks, and 38 000 maxi bricks per nine-hour shift.

VB4X

The pan mixer VB4 brick machine is a versatile, locally manufactured, used brick-making machine.

VB2 Machines

VB2 machines are ideal for small-scale operations with typical production rates of 6 000 M140 hollow blocks, 18 000 stock bricks, and 12 000 maxi bricks per nine-hour shift.