TRUSTED CRAFTSMANSHIP

COMPREHENSIVE TECHNICAL SERVICE RANGE

Delivering Reliable & Cost-Effective Solutions, Keeping Your Operations Running Smoothly

SERVICES

PJR Engineering sources and supplies high-end pre-owed brick machinery to a wide range of satisfied clients across Southern Africa.

Should you require further refurbishment services, we ensure that your high-end brick making machines are refurbished to only the highest standards, saving clients significantly while maintaining high performance and reliability.

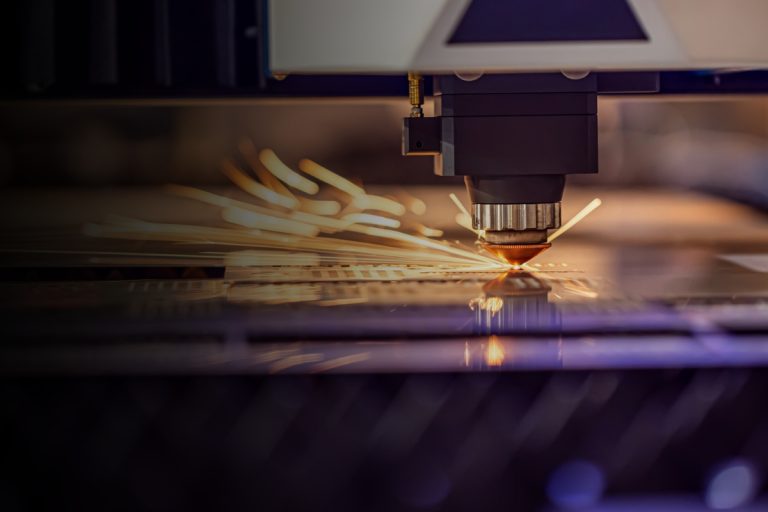

- LASER cutting for mild steel, stainless steel and aluminium.

- We offer precise laser cutting with a size capacity of 1.5m x 3m for a variety of materials.

- Mild Steel: Thickness ranging from 0.9mm to 20mm.

- Stainless Steel: Thickness ranging from 0.9mm to 8mm.

- Aluminium: Thickness ranging from 0.9mm to 12mm.

- Mild Steel PLASMA cutting.

- Our high-resolution plasma cutting service handles mild steel with thicknesses ranging from 0.9mm to 20mm and a cutting capacity of up to 2m x 4m.

- Our precision laser and plasma cutting services ensure consistent, high-quality results for even the most intricate designs. With our quick turnaround times and commitment to excellence, we help you avoid costly errors and keep your projects on track.

- PJR Engineering will inspect the site to determine if the area can accommodate the complete machine before the brick plant installation is sold to a customer.

- Then, we advise the client on the proposed brick plant installation's most suitable placement and layout.

- Next, we will supply drawings for the civil and concrete work. Once this is complete, the brick plant installation can commence.

- Finally, our experienced crew install and commission the plant, always going the extra mile to ensure only the best customer service throughout this process.

- We will dismantle, and transport used brick machines to our workshop in Eikenhof.

- Here we strip the machine entirely and assess the required repairs and refurbishment.

- Next, all components are sandblasted, repaired or replaced, and painted.

- All replacement parts are manufactured to the highest standards.

- In addition, all hydraulic equipment is tested and repaired or replaced.

- Then, all electrical components are replaced. New panels are built with a new PLC program for complete plant automation. All software and hardware become the property of our client.

- Finally, the machine is tested before being shipped to the client.

We manufacture replacement parts for locally produced high-end brick making machines and for 1 000-litre and 1 500-litre counter-current pan mixers.

Our parts are manufactured to the highest standards and specifications. In addition, we can assist our clients if they require modifications to existing used brick machines.

- The parts we manufacture include the following:

- Loading skips

- Feeder boxes

- Mortar silos

- Feeder box arms

- Mixer arms and tools

- Brick and block moulds

- Boom scraper bulkhead

- Hydraulic cylinder repairs

- Tamper parts

CONTACT THE PJR ENGINEERING TEAM TODAY

Expert Advice, Services & Supply of High Quality Pre-Used Equipment For Smart Business Investments